Upright pillar making machine for racking system

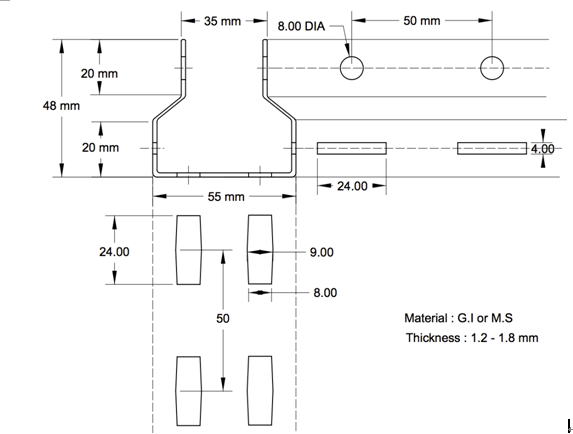

Manufactured from customer special drawing profile, this upright pillar simply clip to your existing or new racking without the need for further fixings. This range of rack upright protectors is suitable for us in temperatures as low as -40 degrees and is fully recyclable and non toxic. With various types punching holes, it is beautiful in appearance and light in weight. Meanwhile it can help you do easy fixing. Here are some pictures for your reference:

For the Racking Roll Forming Machine design plan, we use the following elements and parameters. MACHINE COMPONENTS: 1. Hydraulic decoiler 3 ton 1 set 2. Punching system 64 ton 1 set 3. Coil feeder 1 set 4. Leveling Machine 1 set 5. Roll Forming 1 set 6. Hydraulic Cutting 1 set 7. PLC Control System 1 set 8. Hydraulic Station 1 set 9 .Run-out Table-(Un-powered) set For some key elemetns, here are some introductions:

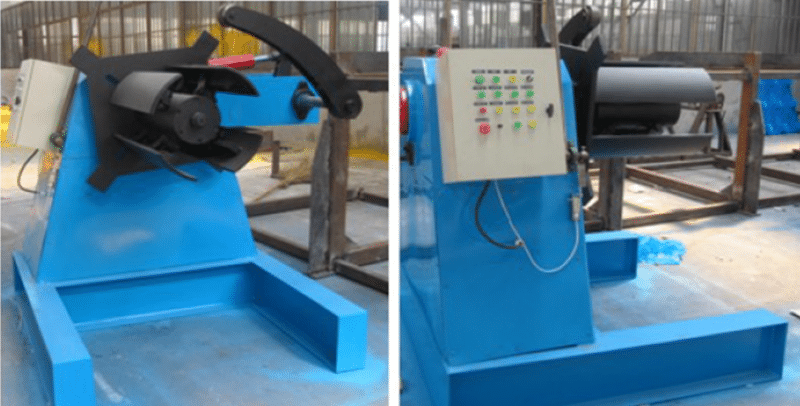

1. Hydraulic Uncoiler: 3 Ton passive de-coiler with brake device Outside diameter of coil: 550mm Inside diameter of the coil: 450mm

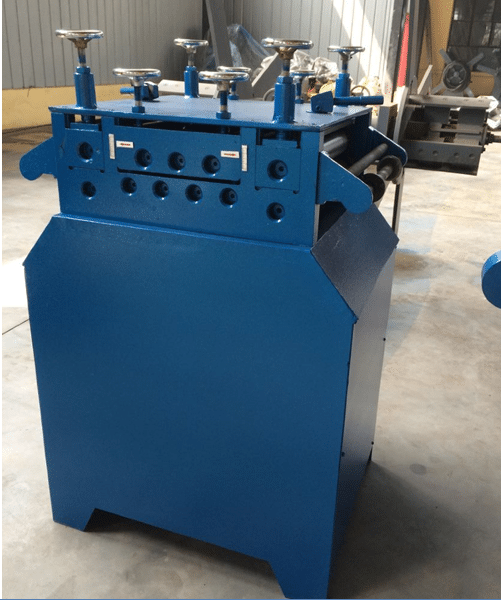

2. Leveling system and coil feeder: After punching holes, the coil feeder can help feed the coil to the machine smoothly and feed coil at same working speed.

3. Main forming machine of Racking Frame Roll Forming Machine : 1) Forming steps: 18 steps 2) Outer diameter: 70mm 3) Machine frame (type): memorial arch frame, Thickness of memorial arch frame: 30mm 4) Roller information: A. Raw material: GCr12MoV B. Quenched degree: 56-58°C 5) Shaft material: 45# steel with heat treat and hard chrome plated on the surface 6) Main motor power: 18.5kw, Reducer ratio: 1:14, Reducer Type: Hardened reducer

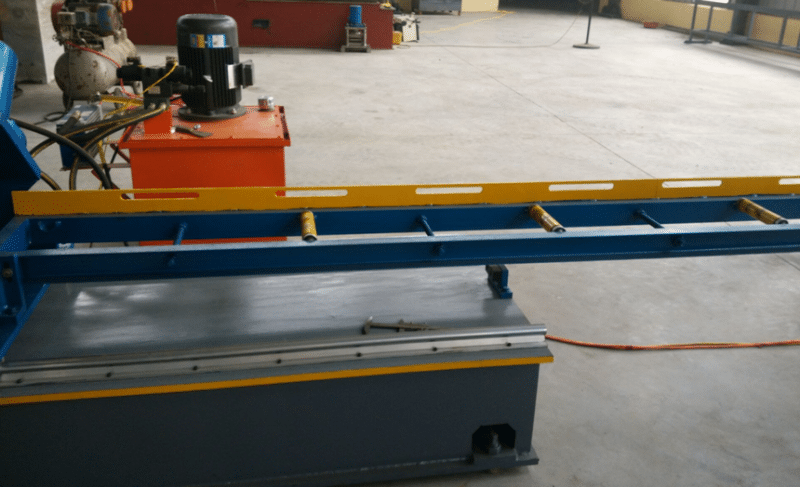

For the runout table:

And for other pallet rack roll forming machines, we also can provide you more detailed information.

Looking for ideal Warehouse Pillar Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Upright Pillar Machine are quality guaranteed. We are China Origin Factory of Sliding Door Track. If you have any question, please feel free to contact us.

Product Categories : Racking Roll Forming Machine

Mr. Cary xu

Mr. Cary xu