New Steel Floor Deck Roll Forming Machine Rollformer

Metal floor deck Roll Forming Machine for cutting floor boards CNC automatic machines, plate-type high-strength galvanized steel floor panels, large-span floor shop contained cement. PLC control, touch screen operation, easy to understand. Greatly improve the efficiency, quality and cheap, affordable and reasonable new brilliant product design, in line with market demand.

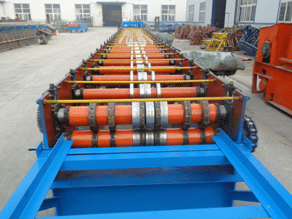

About the machine:

The machine can be single or double layer. Its rollers give the pressure to raw material,then make it morph. Some rollers and axis combine a set of mould,and one mould only can produce one shape,and the mould is not adjustable,and the cost of changed a mould almost can buy a new machine,so if you have two shapes,you can make the machine double layer.

About the produce drawing:

Every shape has it own profile drawing,as i write before, different shape needs different mould,so i need the profile drawing of floor deck,then we can according it design the rollers and axis,then give you a accurate project and price

The machine can be cheap, good and high precision,you can choose as you need.

If you have your own requirement,such as PLC need Panasonic brand,tell me and we will give the detailed cost.

or not,we will provide you the Configuration of ourselves(the good one).

We will design the machine most suitable for you.

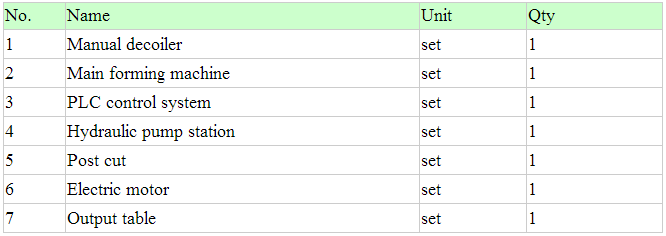

Components of decking making machine

decking making machine Production Process:

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Auto cutting→

Products receiving

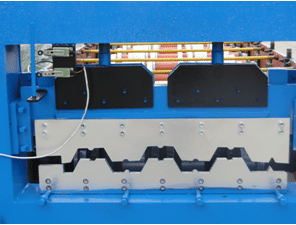

Details of decking making machine:

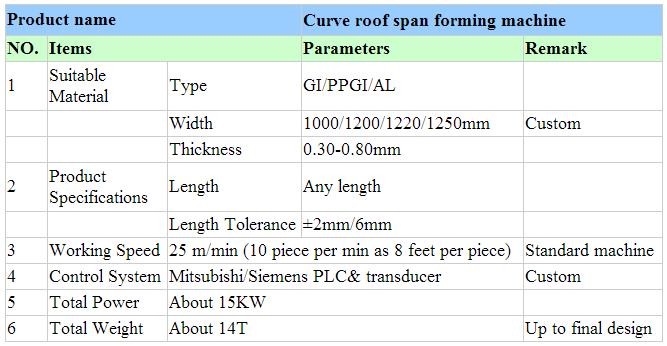

Parameters :

Raw materials of decking making machine

Packaging Detail of decking making machine :

1. One 40ft container for loading one set machine with Manual Decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

ZTRFM has been dedicating to roll forming technologies for over 2 decades and now boasts strong experience, capabilities, innovative thinking and roll forming expertise to provide perfect roll forming solutions to our clients. At ZTRFM, we can help build a better future for you and your customer.

FAQ

1. IS AFTER SALES SERVICE AVAILABLE?

Yes, we offer 7x 24hours online support and our engineers can work oversea to help.

2. HOW CAN I GET TO YOUR FACTORY?

a. First fly to Beijing airport and then go from Beijing Nan to Cangzhou Xi (1 hour) by high speed train . Then we can pick you up at the railway station.

b. First fly to Shanghai Airport and then go from Shanghai Hongqiao to Cangzhou Xi(4.5 hours) by high speed train. Then we can pick you up at the railway station.

3. WHAT IF SOME PARTS BREAK?

We offer warranty of 12 months ,during which free spare parts are available if some parts of the machine break to be irreparable. Besides, we also offer whole life technical support which means we will still offer technical advice 1 year after your purchasing. We can discuss to help you out.

4. CAN YOU TAKE CHARGE OF TRANSPORT?

Yes, we have strong expertise in this area for years and you can trust us.

Looking for ideal New Steel Floor Deck Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the New Roll Forming Machine are quality guaranteed. We are China Origin Factory of Floor Deck Rollformer. If you have any question, please feel free to contact us.

Product Categories : Floor Deck Roll Forming Machine

Mr. Cary xu

Mr. Cary xu